FabLab

FabLab is FIT's professional digital fabrication lab

FabLab provides 3d printing, laser cutting, vinyl cutting and vacuum forming for currently enrolled students; staff, faculty and departments.

Current equipment:

- Universal Laser Systems ILS 12.75 laser cutter

- Graphtec CE-7000 vinyl cutter

- Mayku FormBox vacuum form machine

- 3D printers: Prusa Core One; Bambu Lab X1-Carbon; Form3 & 3L, Ultimaker 3 & 3S, Stratasys F120; Stratasys F370CR

Check out our library of self-help tutorials and videos

Services

All submitted work must be properly setup before the job is started. Files that are not, won't be corrected and will be returned to the customer for correction which may extend the turnaround time.

Students: Need help fabricating a project? Request an appointment with a FabLab Tech.

Faculty and Departments: Class projects must be discussed with FabLab management before being accepted. FabLab-specific orientations may be requested by scheduling an orientation appointment with a FabLab Tech. If help is needed fabricating a part, please complete this form to request a meeting with a FabLab Tech.

>>more about Departmental Services

Services and pricing guide (.pdf)

Forms are pdfs and require Adobe Acrobat or Reader.

Two options:

- Option 1: Vinyl cut single color cutting (no printing).

Available self-adhesive vinyl colors -- white, black, orange red, yellow, green, blue, copper and silver - Option 2: Inkjet print-and-cut onto white or clear self-adhesive vinyl

Note: If you want stickers and prefer to cut them out yourself or don't know how to set up an Illustrator file for cutting, please choose our "specialty media" option to have your file printed onto white or clear self-adhesive vinyl.

Accepted File Type

- Print-and-cut or single color cutting

- Adobe Illustrator files

Cost

- 6" length minimum

- Vinyl cut single color (no printing): $1.00/linear inch

Optional: application tape $0.25/linear inch - Inkjet print and cut: $2.00/linear inch

Guidelines

- Inkjet print-and-cut and single color cutting

- Print-and-cut file setup:

- Outline fonts & link/embed/include images

- Minimum file length is 6"L

- Maximum file size is 21" W x 60" L

- Set up a two layer Illustrator file (art layer and a separate vector layer)

- Setup file exactly how you need to be printed and cut (ie. repeat images, etc.)

- FabLab does not set up nor edit customer files

- Single color cutting file setup:

- Outline fonts

- Minimum file length is 6"L

- Maximum file size is 23" W x 60" L

- Submit a vector based Adobe Illustrator file (the cutter uses the hairline vectors as tool paths)

- Letters must have a minimum height of 1/2"

- Cutout shapes should be a minimum 1/16"

- Setup file exactly how you need it to be cut (ie. repeat images, etc.)

- FabLab does not set up nor edit customer files

- Print-and-cut file setup:

- Application tape (transfer tape)

- Optional when ordering a single color cutting

- Aids in aligning artwork when adhering it in place

Photo is an example of the use of application tape which is an option when using the single color vinyl. It helps to transfer your design to another surface

More information:

We highly recommend asking for a sample to test how the vinyl will adhere to various

surfaces.

Please view our video quick guides:

- Illustrator- Image Trace,

- Vinyl Sticker Application Tape,

- Vinyl Cutting Vector File Setup, and

- Illustrator - Outlining Fonts.

Examples of print-and-cut stickers

3D printing services is full-service only.

Learn about 3D printing with FabLab including policies, procedures and common modeling pitfalls!

First time modeling? Get started with these 3d modeling & sculpting software options such as TinkerCad, OnShape, Autodesk Meshmixer and Maxon ZBrushCoreMini.

Some examples of 3d printing in the real world.

Accepted File Type

.stl

Costs and Build Sizes

Stratasys F370CR: Soluable support material. Industrial-grade, high quality.

- Build tray dimensions: 14"L x 10" W x 14"H

- Filaments: ABS and TPU

FormLabs Form3 & 3L: Support material removed by customer. All print extremely high detail using a variety of specialized plastic resins. They utilize stereolithography, fusing photo-sensitive polymers into solid objects with focused points of light. Stereolithography allows for much higher detail than FDM printing, as well as printing in flexible and castable resins, but the Forms have a smaller print bed and a more involved support-removal process.

- Form3 build tray dimensions: 13.2"L × 7.9"W × 12.6"H

- Form3L build tray dimensions: 13.2"L × 7.9"W × 11.8"H

- Resin: ($5.00 minimum charge). $0.50/ml

Ultimaker 3 & 3S: Soluable support material. Capable of dual or single extrusion.

- Build tray dimensions: Left or right nozzle: 8.5"L x 8.5"W x 7.9"H. Dual material: 7.8"L x 8.5"W x 7.9"H

- Filament: PLA plastic: ($5.00 minimum charge). $0.50/g; specialty filaments $0.75/g. PLA plastic & specialty filaments include white TPU, PETG, PVA, CopperFill, WoodFill, BronzeFill, Magnetic Iron, Stainless Steel, Carbon fiber, F-Electric and more

Stratasys F120: Soluable support material. Industrial-grade, high quality.

- Build tray dimensions: 10"L x 10"W x 10"H

- Filaments: ASA ivory & ABS black plastic: ($5.00 minimum charge). $7.00/cubic inch

Bambu Lab X1-Carbon; H2D; H2D Laser: Support material removed by customer.

- Build size: 10"L x 10"W x 10"H

- Filament: PLA plastic: ($5.00 minimum charge). $0.35/g. Colors based on availability

Prusa Core One: Support material removed by customer.

- Build tray dimensions: 10"L x 10"W x 10"H

- Filament: PLA plastic: ($5.00 minimum charge). $0.35/g. Colors based on availability

Guidelines

Customer responsible for paying for both build and support material. Submitted files must be set up according to our file prep guidelines. Please view our 3d video guides for additional information. We will not correct files that are set up incorrectly and will return them for correction which could extend turnaround times.

Autodesk Netfabb is a free STL viewer which can open your 3d files and diagnose inverted normals/faces and bad edges. Please see our Netfabb video tutorials for cleaning and repairing guidance. Netfabb is free and available to download.

Measurements in NetFabb: In the bottom right panel of the NetFabb window, you will see basic dimension information about your part, including size and volume, which can be used to estimate your cost (not including support material). For a more detailed guide on how to use Netfabb to measure and resize your models, please view our video guide.

Support Material

All 3d printers generate support material differently, and all support material types

have different post-processing and finishing requirements. The Ultimaker and Stratasys

F120 have dissolvable support material but the Form and Bambu printers do not so customers must clip or sand away their support structures manually.

Example below: Garment designed by Jennifer Lee (Assistant Professor, FBM). Model is Jasmine Matos (FIT tennis player, FBM student). Photographer is Anthony Nguyen (FBM student).

Highlights of the vacuum forming machine:

- Food safe transparent sheets;

- Great for product packaging, prototyping, mold making, blister pack, and more.

- Can be used with concrete, jesmonite, plaster, chocolate, wax, soap, resin, and many other materials.

Choice of either transparent 0.5mm sheets made from food safe, recyclable PETg or white sheets made of Polystyrene, which can be painted and are good for blister and product packaging and prototyping.

The surface finish achieved is almost identical to that of the original object. Use in conjunction with a 3d printer and create molds of your 3D printed designs.

Maximum width and length for mold making: 5.9"x5.9".

No vacuum forming objects taller than the object's width.

Costs: $3.00 per mold sheet, clear or white

Guidelines: Please view our video guide: Vacuum Forming: Making Molds & Shapes Quick Guide

Service includes laser vector cutting, vector engraving and raster engraving.

The FabLab is equipped with a Universal Systems ILS 12.75 laser cutter which has a material processing platform of 48” x 24” x 12”.

Accepted File Types

- Submit Photoshop .jpeg files for raster engraving

- Submit Adobe Illustrator files for vector cutting and vector engraving

Accepted Materials

Download our laser cutting acceptable materials & supplier guide (.pdf) for local suppliers and online vendors. We reserve the right to refuse material if we deem it to be unsafe or inappropriate. Guide is a pdf and requires Adobe Acrobat or Reader.

- Materials can be 1/4" thick for vector cutting: This thickness is a general guideline because it depends on your design and the density of the material. Acrylic; Softwoods such as poplar, pine, balsa, cherry, walnut, soft maple; Paper based materials such as cardboard, bristol board, museum board , chipboard, etc.; MDF and CDF; Natural Fabrics

- Materials need to be no more than 1/8" thick for vector cutting. This thickness is a general guideline because it depends on your design and the density of the material. Generally we accept leather; hardwoods (ex: ash, birch, hickory, elm, oak, hard maple, etc); cork; rubber; faux leathers (faux leathers have to be approved by a FabLab techician)

- Materials that are paper heavy stock products such as chipboard, illustration board,

poster boards, museum boards, etc.

- Due to limited storage space, we are not accepting 24"x48" materials unless the cut

file's bounding box follows these guidelines:

- A cut file canvas should be setup as landscape

- A cut file canvas must have 1/4" margin or more

- Due to limited storage space, we are not accepting 24"x48" materials unless the cut

file's bounding box follows these guidelines:

Accepted Margins

1/4" around entire laser cut file. Material size should be no more than 1" to 2" larger than your cut files bounding box. We have a board trimmer for softer paper products that you can use to trim your board down to size.

Costs

Initial setup fees:

- Standard job $7.00 setup charge/material

- Complex job $10.00 setup charge/material

After the initial setup fee (per material), the price for use of the laser (for vector cutting, vector engraving, and raster engraving) is $1.00 per minute.

Guidelines

Please view our video quick guides: Illustrator - Vector File Setup, Illustrator - Pattern Creation and Illustrator - Outlining Fonts.

- To ensure a smooth cut, join your vectors

- Remove all duplicate lines to prevent double cuts

- Work in RGB document color mode

- Do not use masks or pattern fills

- Do not use appearance strokes such as dashes

- Label your material with your name on the side you want to cut

- Scorched edges: Paper or tree-related material will most likely have burn marks or scorched edges which we are not liable for.

- Send your file and order form to [email protected] first before dropping off materials

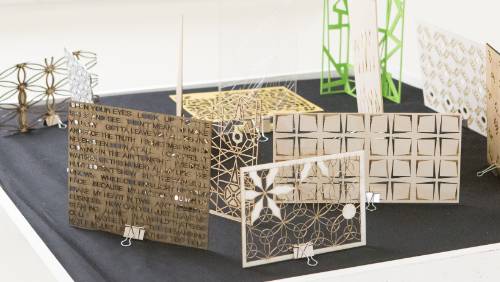

Project examples:

Melanie Reim, acting associate dean of the School of Art & Design. Wood laser cut submission for The Art & Design Gallery exhibit, "Conversations: Artwork In Dialogue" March through April 2020. The dialog between the two female 'sand puppets' reads: "And I like, said, it's not what I need, and he said, "I know, I know, I know, I know, I know, I know, I know, I know".

Interior Design Department, Studio V-Residential. Challenged to prototype a laser cut element for their residential project, students developed designs that were fabricated here at the FabLab. Professors: Joseph Lembo, Takashi Kamiya and Johannes Knoops

T. Jacob Hooker, Accessories Design graduate. Laser cut leather accessory for the BFA graduating student show.

Hojun Lee, Fashion Design graduate. Laser cut dress